SHERPA

Improve Mining Cost Estimates with SHERPA

Enhance the precision and dependability of your mining cost estimates while streamlining the time invested with SHERPA. From initial financial evaluations to reclamation, SHERPA provides the essential data combined with advanced models and algorithms, enabling accurate cost calculations at every phase of your mine’s life cycle.

Built upon industry-standard engineering-based estimating procedures while encompassing the extensive dataset of our Mining Cost Service, SHERPA equips you with the necessary tools to quickly and accurately determine both capital and operational costs for all facets of your mine project.

Comprehensive Data from Mining Cost Service

With access to the robust dataset of the Mining Cost Service, SHERPA covers all the bases. All necessary salaries, hourly wages, equipment, and supply prices are directly sourced from our cost database, enabling quick estimates with minimal project details.

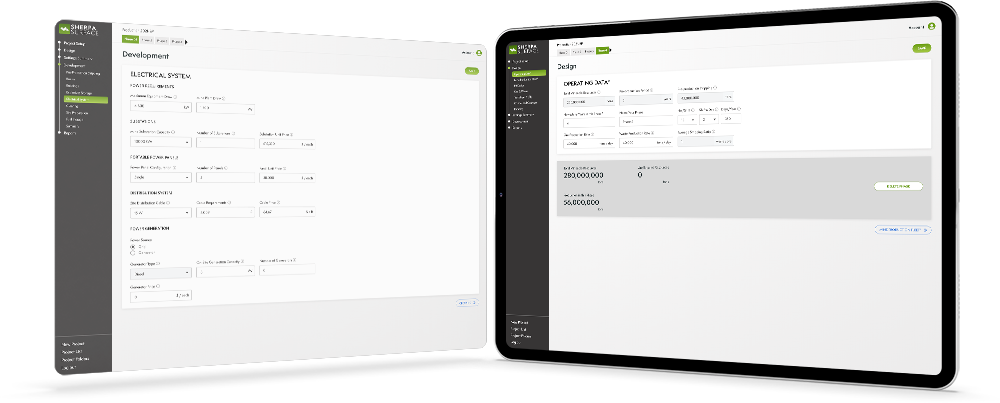

Fully Adjustable Inputs

Tailor your estimates to perfection with SHERPA’s fully adjustable inputs. While our models come complete with suggested values for standard variables, you have the flexibility to customize each item. Whether adjusting for local conditions or running alternate scenarios, SHERPA empowers you to input your expertise directly into the calculations.

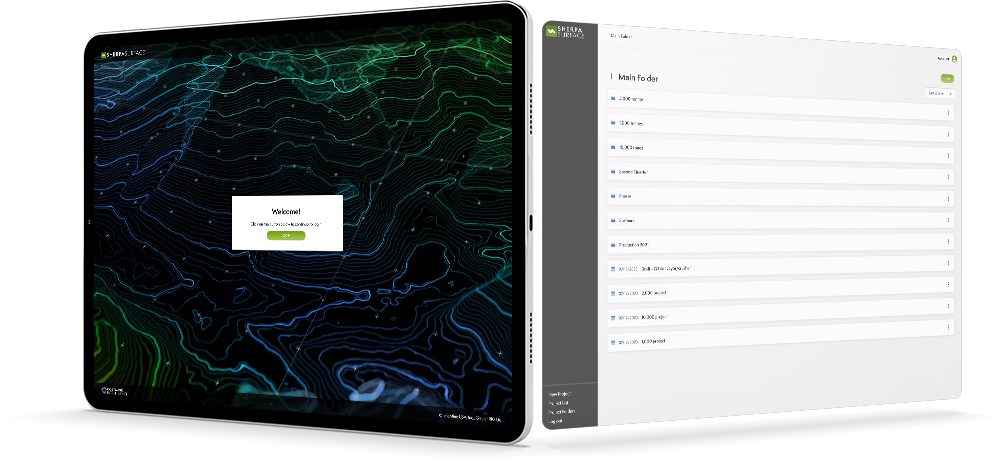

Easy-to-Use Interface

Navigate the estimation process with ease using our modern, cloud-based interface. Designed for efficiency, you can swiftly move through input screens with lightning speed. Finding and modifying values is intuitive, with tooltips providing guidance on each input’s purpose and the application’s suggested values.

Detailed Reports with Data Visualization

Generate comprehensive project output reports with ease. From Executive Summaries to Total Project Cost Summaries, visualize your estimations in various formats. Export reports in PDF for seamless sharing and analysis with your team.

SHERPA is your all-in-one solution for mining cost estimation, fueled by Costmine. Unlock the potential for accurate, reliable, and efficient cost projections for your mining projects.

Models

Surface and Underground

Calculate costs for almost any mining project, whether it’s an open-pit, cut and fill, room and pillar, and more. Cost data and engineering parameters are included for nearly any condition you might encounter whether your project is surface or underground.

Reclamation

Environmental impact has never been more important than it is right now, and our reclamation cost models will ensure that you’re prepared for every step during and after mine closure. Keep track of and easily update their reclamation cost estimates for a mine from concept to closure.

Mineral Processing

Our mineral processing models calculate the operating costs and capital expenditures associated with mineral processing plants. Based on data supplied by the user, SHERPA suggests a flow sheet and emulates flow through the plant to arrive at material balance. Along with processing, SHERPA will also estimate engineering requirements for a variety of ancillary facilities, such as a tailings impoundment, water supply and treatment system, mill building, power supply, and even a project camp, if required.

Apex

Produce a complete cash flow schedule for your project and compute the projected net present value, pay-back period, and internal rate of return on either a before- or after-tax basis with our financial evaluation models. You can easily compute the breakeven value for any of the data items you entered, such as ore grade, production rate, stripping ratio, smelting charges, or mining costs. Powerful risk and sensitivity modules allow you to examine the economic effects of variations in the data elements

How does it work?

Our Approach

The cost estimating techniques used by SHERPA rely on a number of project-specific engineering parameters, such as material densities and swell, powder factors, rolling resistance, drill penetration rates, drill bit and rod wear, stoping methods, and bench heights. These parameters, along with user specified haul profiles and ore and waste production rates, provide the foundation upon which the cost estimate is based. You may, of course, enter all these values directly into the application and manipulate them as needed. However, in cases where some or all of this information is unavailable, the SHERPA applications suggest reasonable entries. In addition to its suggested entries, our tooltips provide guidance in determining alternate values.

By suggesting entries for required fields in SHERPA Surface, for example, the applications allow you to complete reasonable estimates in a short time by specifying only a limited amount of information, such as the daily production rate, shift schedules, haul distances and gradients, and the total resource size. You can leave the rest up to SHERPA, or you can alter any and all of the suggested parameters as desired.

Equipment Selection

Once production and deposit data have been entered, the applications will begin the process of selecting equipment. Either specify your own fleet or allow SHERPA to build it for you based on your project specifications. In the case of SHERPA Surface, if the application suggests the fleet, an optimization process determines the most economically attractive excavator/hauler combination. Standard engineering techniques are used to select the types and determine the sizes of the remaining equipment in the Surface fleet and in the other SHERPA applications.

Equipment productivities are determined using widely accepted engineering techniques. Equipment availability, bucket fill factors, material densities and swell, fixed cycle times, and travel speeds (adjusted for load and gradient) are all considered when determining productivity. In SHERPA Processing, the application emulates material flow through the processing plant to determine a material balance. Using the flow rates, size fractions, and solids densities, the application selects the equipment and determines the capacities required.

Once the equipment has been selected in SHERPA Surface, the program examines the specified powder factors, bench heights, and production requirements to select the type and determine the size of the blasthole drills. Requirements for ancillary equipment, including graders, pumps, dozers, lighting plants, water tankers, pick-up trucks, maintenance trucks, and explosives loaders are also provided. Again, you can alter any or all of the fleet selected by the application by simply overwriting the suggested values.

Cost Estimates

With the equipment fleets specified, the applications begin the task of determining requirements for all other aspects of the operation. The numbers of hourly and salaried workers required to meet the specified production rate are estimated. Consumption rates for all pertinent supplies, including blasting materials, drill bits and rods, diesel fuel, electricity, repair parts, lubricants, and tires are calculated. The sizes of the shop, mine office, change house, and warehouse are provided, as are requirements for explosives storage facilities and the electrical distribution system. The application also estimates pre-production development and haul road requirements, as well as working capital, engineering, and management parameters.

Once all necessary cost engineering parameters have been determined, they are used in conjunction with the information contained in our cost database to calculate all relevant capital and operating costs. The results are then displayed under the Reports section of your project.

Who is SHERPA for?

SHERPA is an all-in-one package designed for cost estimators and engineers who need quick, reliable cost estimates for their projects. Whether you’re starting from scratch, or simply want to sanity test your own estimates, SHERPA contains all of the necessary data, models, and algorithms to ensure that your work adheres to highest standard of quality in the mining industry.

Want to learn more about SHERPA and how it can help you streamline your mining cost estimation process?

Request a demo with a member of our team to get a hands on tour of the SHERPA suite of mine cost estimation software.